Das goldene Zeitalter der Decolletage-Drehmaschinen ist wahrscheinlich in der Mitte des vergangenen Jahrhunderts anzusiedeln, als sich drei Schweizer Unternehmen den Markt teilten und zehntausende Kurvendrehautomaten verkauften. In den sechziger Jahren tauchten kleine, auf Überholungsarbeiten spezialisierte Unternehmen auf. 50 Jahre später erfreut sich dieser Bereich blühender Geschäfte und bietet interessante Perspektiven. Wir führten ein Gespräch mit Herrn Carlos Cancer, dem CEO der Seuret SA, die seit 1964 auf Überholungsarbeiten spezialisiert ist.

Das Unternehmen Seuret SA gehört seit 2011 der Gruppe Humard Automation SA an. Das Unternehmen wird 2014 fünfzig Jahre alt; zu diesem Anlass wird ein ultramodernes Werk in Delémont gebaut, das den Mitarbeitern der Seuret SA einen völlig neuen Rahmen bieten wird; darüber hinaus wird sich das Unternehmen auf einen neuen CEO stützen können, der viel Erfahrung in den Bereichen Verkauf und Management von Referenz-Industrieunternehmen des Bereiches mitbringt.

Sobald die alten kurvengesteuerten Maschinen geschabt, frisch lackiert und

neu zusammengebaut sind, erleben sie eine neue Jugend, und die Kunden

können davon ausgehen, sie mehrere Jahrzehnte hindurch einzusetzen.

Ein umfassendes Zusatzangebot

Der Drehautomat mit numerischer Steuerung Dec‘ Humard, den wir in unserer September-Ausgabe des Vorjahres vorgestellt hatten (der Artikel ist als Download verfügbar, siehe Ende des Artikels), fördert die Schlüsselkompetenzen der Seuret SA in Bezug auf alle hochpräzisen Bearbeitungs- und Zusammenbauvorgänge. Herr Cancer führte näher aus: „Die Dec’ Humard beruht auf drei wesentlichen Punkten: auf dem Grundkonzept, das in Zusammenarbeit mit der Elwin SA – einer perfektionsorientierten Zulieferfirma der Uhrenindustrie – entwickelt wurde, auf der Stärke und industriellen Zuverlässigkeit der Humard Automation SA sowie auf den Mikrotechnik-Kompetenzen der Seuret SA. Diese Maschine ist hauptsächlich für Unternehmen bestimmt, die für den Luxusuhrenmarkt arbeiten. Diese Unternehmen sind ihrerseits an kurvengesteuerten Drehautomaten interessiert, um die Teile in zunehmend größeren Serien herstellen zu können. Somit finden sie in unserer Gruppe alles was sie benötigen.“

Kurvengesteuerte Maschinen im Jahre 2014? Eine zukunftsträchtige Lösung!

Manche Decolletage-Unternehmen haben beschlossen, alles auf numerische Steuerung zu setzen und die alten kurvengesteuerten Maschinen aus ihren Werkstätten zu verbannen, andere machen es genau umgekehrt und möchten überholte kurvengesteuerte Maschinen in ihren Werkstätten einführen. Die drei nachstehend angeführten Argumente widersprechen dem, was man auf dem Markt ständig hört; das mit Herrn Cancer geführte Gespräch zeigt, dass kurvengesteuerte Maschinen 2014 sehr gefragt sind.

1 – Es gibt qualifizierte Bediener

„Der Decolletage-Bereich hat sich im Laufe der Zeit weiterentwickelt, und verschiedene Unternehmen bilden Decolletage-Arbeiter auf kurvengesteuerten Maschinen aus. Ihre Kompetenzen sind anerkannt und sehr gefragt, daher werden solche Facharbeiter auch gut bezahlt“, antwortete Herr Cancer. Wenn man sich darüber hinaus das Personal der Seuret SA etwas genauer ansieht, stellt man fest, dass junge, von Leidenschaft beseelte Leute dabei sind, die am Fortbestand der Tradition festhalten.

2 – Kurvengesteuerte Maschinen sind präzise

„Die Anforderungen, sowohl was die geometrische Präzision und Dimensionsgenauigkeit als auch den Oberflächenzustand anbelangt, sind wesentlich höher als früher, insbesondere im Bereich der Uhrenindustrie – eine von Seuret SA überholte Maschine wird allen diesen Anforderungen gerecht „ erklärte der Geschäftsführer. Das seit 50 Jahren auf Überholungen spezialisierte Unternehmen verfügt über ein auf der ganzen Welt wahrscheinlich einzigartiges Know-how, wodurch es in der Lage ist, Maschinen anzubieten, die hinsichtlich Qualität und Präzision beispielhaft sind.

3 – Eine Überholung ist wirtschaftlich rentabel

„Die Kosten einer kompletten Überholung sind nicht vernachlässigbar, nichtsdestoweniger liegen sie weit unter den Anschaffungskosten von neuen Maschinen. Sobald die Drehautomaten überholt sind, bieten sie sehr hohe Produktionsleistungen, und das mehrere Jahrzehnte lang“, fügte Herr Cancer hinzu.

Zahlreiche Dienstleistungen werden geboten

Die Überholung von mechanischen Maschinen, hauptsächlich von kurvengesteuerten Einspindeldrehmaschinen, ist das Kerngeschäft der Seuret SA, aber das Unternehmen überholt auch andere Maschinentypen wie zum Beispiel Verzahnmaschinen. Herr Cancer führte näher aus: „Wir haben sehr viel Erfahrung in diesem Bereich und bereits hunderte Maschinen überholt. Wir überlegen, unsere Tätigkeit auf andere Maschinen zu erweitern, die dieselben Kompetenzen erfordern.“ Der Geschäftsleiter äußerte sich nicht weiter zu diesem Thema, aber wir können uns gut vorstellen, dass beispielsweise von Mehrspindeldrehautomaten die Rede ist. Abgesehen von Überholungsarbeiten bietet das Unternehmen Seuret auch Störungsbehebungen von kurvengesteuerten Maschinen sowie einen leistungsstarken Ersatzteilservice.

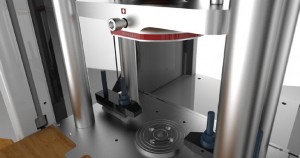

Ein Tornos M4-Rahmen, der für den Zusammenbau bereit ist.

Den Maschinen neues Leben einhauchen

Eine Maschine, die die Werkstätten der Seuret SA verlässt, ist wirklich neuwertig: Sie ist frisch lackiert, die Rahmen und Schlitten wurden geschabt und gemäß Toleranzen von wenigen Mikron zusammengebaut… Sie sehen wie neu aus. Herr Cancer erklärte uns: „Die Maschinen werden auf den neuesten Stand gebracht, um den höchst anspruchsvollen Präzisions- und Qualitätsanforderungen der heutigen Märkte (zum Beispiel die Uhrenindustrie) gerecht zu werden. Unsere Kunden bestätigen uns, dass die von uns gebotenen Maschinen die besten auf dem Markt sind.“ Der Geschäftsleiter fügte abschließend hinzu: „Als Ergänzung zu den numerisch gesteuerten Drehmaschinen interessieren sich heute wieder viele Unternehmen für dieses Produktionsmittel, das sehr hohe Leistungen zu äußerst wettbewerbsfähigen Preisen bietet. Wir sind da, um ihnen dabei zu helfen in der Schweiz und Europa.“

Die Seuret SA in Delémont!

Wir wollten wissen, welche Folgen der Einzug in die neuen Geschäftsräume in Delémont (im zweiten Halbjahr 2014) für die Kunden haben wird. Herr Cancer erklärte uns: „Hinsichtlich Produktqualität und Leistungen ändert sich nichts. Wir sind dafür bekannt, einen erstklassigen Service zu bieten, und das werden wir auch weiterhin tun. Die erheblich besser geeigneten Räumlichkeiten und angenehmeren Arbeitsbedingungen unserer Mitarbeiter werden Produktqualität und Service zunutze kommen. Da wir den Geschäftsräumen der Humard Automation SA geografisch näher sein werden, können wir die Synergien der verschiedenen Tätigkeiten

der Gruppe in Zukunft besser nutzen.“ Zunächst ist nicht vorgesehen, die kurzfristigen Lieferkapazitäten erheblich zu erhöhen; der CEO nahm diesbezüglich ganz klar Stellung: „Wir haben Marktanalysen durchgeführt und haben selbstverständlich klare Vorstellungen was die Zukunft anbelangt; es ist ein großes Potential vorhanden, aber wir wollen kein Wachstum um jeden preis.“

Source: Eurotec No 393 (02/2014)

English version

French version

Born in 2012, Izmade is a sustainable design collective from Turin, Italy that specializes in the field of self-made eco-design furniture and home accessories. Izmade’s products are the result of a marriage between a traditional approach to conceptual design and an artisanal, self-made approach to production. Our design process is centered around environmental sustainability and the enhancement of a material’s original features to create something new and beautiful.

Born in 2012, Izmade is a sustainable design collective from Turin, Italy that specializes in the field of self-made eco-design furniture and home accessories. Izmade’s products are the result of a marriage between a traditional approach to conceptual design and an artisanal, self-made approach to production. Our design process is centered around environmental sustainability and the enhancement of a material’s original features to create something new and beautiful.

Swiss Made is a registered trademark that denotes products that are made in Switzerland. It is such a value for the manufacturer and the consumer that its designation is regulated, protected and controlled by Swiss law.

Swiss Made is a registered trademark that denotes products that are made in Switzerland. It is such a value for the manufacturer and the consumer that its designation is regulated, protected and controlled by Swiss law. 19 new machines

19 new machines

Have you ever wanted to attach a file in an email and you can’t find or access it from your phone? The team behind the new email app Gusto has shared that frustration.

Have you ever wanted to attach a file in an email and you can’t find or access it from your phone? The team behind the new email app Gusto has shared that frustration.

Sales of Tesla’s battery-powered vehicles, priced from about $70,000, totaled around 22,450 last year. “With 6,900 deliveries in the [fourth] quarter [Tesla’s Model S sedan] is still a niche vehicle,” Kevin Tynan, an auto analyst for Bloomberg Industries told Bloomberg. According to the company’s annual report, as of December 31, 2013, it had 2,964 full-time employees world-wide. (The percentage of those employees who work in the U.S. was not released in the report. An inquiry to Tesla was not immediately returned).

Sales of Tesla’s battery-powered vehicles, priced from about $70,000, totaled around 22,450 last year. “With 6,900 deliveries in the [fourth] quarter [Tesla’s Model S sedan] is still a niche vehicle,” Kevin Tynan, an auto analyst for Bloomberg Industries told Bloomberg. According to the company’s annual report, as of December 31, 2013, it had 2,964 full-time employees world-wide. (The percentage of those employees who work in the U.S. was not released in the report. An inquiry to Tesla was not immediately returned).

You know what they say: It’s easier to keep a customer than it is to find a new one. It’s also far cheaper – 6 to 7 times less expensive, according to Flowtown. That’s why it’s essential for every business to have a strategy to boost loyalty and keep customers coming back for more.

You know what they say: It’s easier to keep a customer than it is to find a new one. It’s also far cheaper – 6 to 7 times less expensive, according to Flowtown. That’s why it’s essential for every business to have a strategy to boost loyalty and keep customers coming back for more.

This animal-shaped key ring-sized pocket toolbox is specially designed for a niche sports market and contains every tool necessary for snowboarding, skateboarding and surfing, as well as being appropriate for a wide range of other uses. The inspiration for this compact and multipurpose design was the intended user: a lover of the outdoors, of nature and of the wilderness. The environmental characteristics of this design were therefore critical to its success as a product. It would have been considered irresponsible to design multiple products for this user group using up to 10 times the amount of materials for 10 different tools, including the resultant consumption of energy that this would have required, when an all-in-one tool would suffice.

This animal-shaped key ring-sized pocket toolbox is specially designed for a niche sports market and contains every tool necessary for snowboarding, skateboarding and surfing, as well as being appropriate for a wide range of other uses. The inspiration for this compact and multipurpose design was the intended user: a lover of the outdoors, of nature and of the wilderness. The environmental characteristics of this design were therefore critical to its success as a product. It would have been considered irresponsible to design multiple products for this user group using up to 10 times the amount of materials for 10 different tools, including the resultant consumption of energy that this would have required, when an all-in-one tool would suffice.